Due to the good reception of the audience of the site, we decided to publish more articles in this field.filteration:Filtration is the process of separating suspended solids from liquid, which causes the solid to pass through the pores of a material called a filter. The filter may be paper, cloth, cotton wool, asbestos, slag or glass wool, unglazed earthenware, sand or other porous material. Application of filtration:Filtration is often used in chemical technology and often presents many problems. In most technical operations, cotton cloth is the filter material, but sometimes wool or hair cloth is necessary. The cloth can be set on a wooden frame to form a shallow bag into which the turbid liquid is poured. In this case, the filter will be cloudy at first, but will soon become clear, and then the cloudy part will return to the filter. Filtration is often delayed by the presence of fine, slimy deposits, or by the formation of crystals in the interstices of the cloth, from the hot solution. Any attempt to hasten filtration by scraping or agitating the sediment on the cloth will always cloud the filter. Types of filtration:Bag filtration:which is a long, narrow knife made of cotton supported by an outer covering of coarse and strong net. It is able to withstand considerable weight and hydrostatic pressure. These bags are often five or six feet long and eight inches or more in diameter. The open end of the bag is tightly closed around a metal ring or a nipple, by which the whole is suspended. Through it, the desired liquor is filtered. When hot liquids are filtered, the bags are often hung in steam-heated rooms. Pressure filtration:The liquid passes through the filter layers with direct atmospheric pressure, and the air is expelled from the receiver. or by hydrostatic pressure obtained by using a high column of liquid or by a power pump called a suction filter. How the filter works:The liquid may be directed through the filter to the receiver. Sediment accumulates on top of the filter and becomes part of the filter layer. This sometimes causes problems, because the unit particles of certain sediments form an impermeable layer. or it may be drawn up through the filter suspended in the liquid to be filtered. Therefore, clogging does not happen as easily, because a large part of the sediment sits at the bottom of the container and does not contact the filter until most of the liquid has been removed.

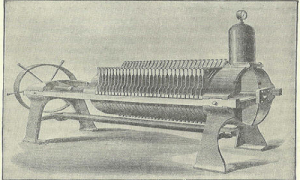

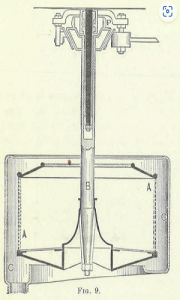

Available pages in filtration:The pressure is usually achieved by a filter press. It is a strong iron frame in which a number of oriental iron or bronze filter cells are supported. Each cell consists of two flat metal plates with raised edges separated by a hollow “spacer frame” of the same metal. There is a hole in the center of each plate, and there are grooves on each surface that lead to an opening at the bottom edge of the plate. A filter is made of two pieces of cloth, slightly larger than the plates, sewn together along the edge of a small circular opening cut in the center of each. A piece of cloth is passed through the hole of the plate and then both pieces are spread softly, one on both sides of the plate.

Another way of sedimentation:In another form of press, instead of a central opening, there is a hole in the cornel of each plate and spacer frame so that when placed in the press, the holes form a continuous channel through the corner of the whole. Series of cells A small hole inside each spacer frame, at right angles to the direction of the channel, admits fluid into each cell. The filter is a piece of cloth that is hung over the spacer frame so that it covers both sides of the frame. A frame therefore Covered is placed between each pair of grooved plates. Small holes are cut in the fabric to match the channel in the corners of the cell. The filtration method is the same as central feeding devices

The pressure achieved by a power pump may be only a few pounds or may increase to several hundred pounds per square inch. A filter press may have from one cell to fifty cells or more, and these cells may be as large as four feet in diameter. For many purposes, the press is surrounded by coils or jackets, through which steam or cooling solutions may circulate. According to the desired cold or hot filtration. The filter press is very fast and widely used in industrial chemical work. For use with acidic or corrosive fluids, spacer plates and frames are often coated with lead or alloys that do not corrode easily. |