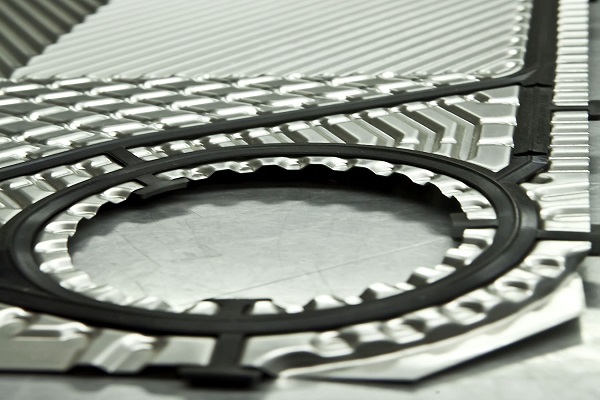

They are suitable for industrial and civil applications that require the use of insulating materials and are used in the insulation of air conditioning, refrigeration, heating, plumbing, tanks, fittings and air ducts.

elastomeric insulation

Elastomeric insulation is one of the most practical insulations that can be used in many different materials.

It can also be pointed out that elastomeric insulation is one of the most durable insulations produced in which it is used in many different industries, the most important of which is the use of this insulation in the construction, petrochemical, oil, Gas, automotive, food, health and chemical.

Elastomeric insulation has a heat and cold resistance of -200 to +105 and this factor has caused this insulation to have high sales among other production insulations.

types of elastomeric insulation

Elastomeric insulation has many different models, including tubular elastomeric insulation, roll elastomeric insulation and flexible duct with elastomeric insulation, each of these products can be used in various applications.

Tubular elastomeric insulation:

The length of tubular elastomeric insulation is 2 meters and its thickness is 9, 13, 19, 25 mm. Tubular elastomeric insulation is produced and supplied in diameters of 6mm to 114mm.

Rolled elastomeric insulation:

1000 mm wide roll insulators are ideal for insulating aluminum ducts, large surfaces and large diameter pipes.

By reducing the number of steps required for insulation, we will have easier installation and save time and labor costs. Elastomeric insulation is flexible and has a high durability.

The standard thickness for roll insulation is 6,10,13,16,19,25,32,50 mm

Roll elastomeric insulation is available in simple and adhesive form.

Elastomeric insulation properties

- Very low heat transfer coefficient

- Resistant to biological contamination

- High stability

- Resistant to ozone and ultraviolet

- Corrosion resistant

- Easy to install with self-closing

- No fiber and no dust production

- flexible

- High adhesion and color acceptability

- Resistant to pressure and impact

Other features of these insulators include the following:

- Corrosion resistant

- Very high resistance to water vapor penetration (7000 ≥ µ)

- Very light with a specific weight of 45 to 65 kg per cubic meter

- Resistant to corrosion in very bad weather conditions

- Eco-friendly, no CFC and HCFC emissions

- Very low heat transfer coefficient

- Easy and fast installation and repair

- High resistance to sound transmission in air ducts and pipes

- High resistance to aromatic compounds and hydrocarbons

- High resistance to oils, acids and bases

- No dust production

- flexible

- Resistant to pressure and impact

- Non-toxic

- Impossibility of growth of fungi and bacteria in it

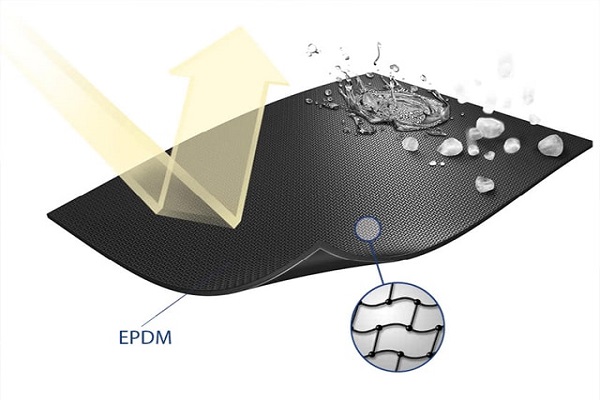

What is elastomeric insulation (made of EPDM)

Polyethylene and polypropylene are polymers with very low glass transition temperatures and have a crystalline nature, which due to this nature, has no rubber properties and is used as a plastic.

By copolymering ethylene and disrupting the structural order of each homopolymer, the crystallinity property can be separated from the polymer and a polymer with a rubber property can be created.

The copolymer formed by this special method is called EPR, which has a completely saturated nature and due to this, has a high atmospheric and thermal resistance.

However, due to the lack of double bonding in the chemical structure, this elastomer lacks sulfur curing capability and can only be cured with a peroxide curing system.

To solve this problem, a third monomer, the DN monomer, is used in reaction with ethylene and propylene.

In this way, a terpolymer is obtained that contains a double bond and is capable of curing sulfur, which is called EPDM.

Adhesive elastomeric insulation or EPDM elastomeric insulation is very suitable for cold and tropical regions, so that the degree of temporalization, oxidation and aging due to its heat is very low and insignificant and resistant to organic and inorganic chemicals.

Also, its chemical resistance (elastomeric insulation) against insoluble based products is low.

source : tajhiz sanaat weblog