In the dairy industry, the use of the most up-to-date common standards in the design and construction of the wastewater treatment system of the dairy industry is the most important feature of the systems in the technical design and work engineering company. Performing detailed analyzes on raw wastewater of the dairy factory and calculation and codified design considering all economic parameters, engineering and obtaining environmental approval in this regard are other features of the wastewater treatment system of the dairy industry.

Definition of dairy industry

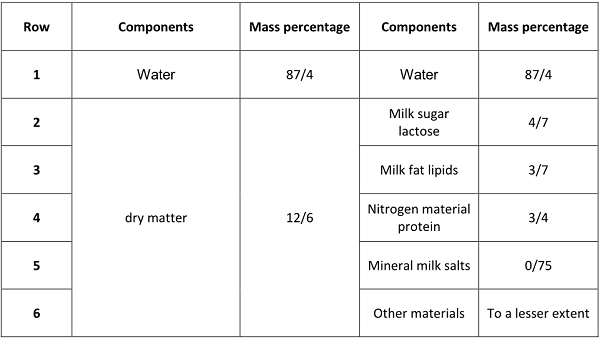

Dairy industries are industries in which milk is received as a raw material and then converted into various products during its industrial processes. Milk contains water, fat, protein, lactose, minerals (minerals) and various vitamins. Although the composition of each milk varies depending on the type of livestock (cow or sheep), breed and nutrition, in general, the composition of cow milk, which is used by almost all major factories, can be considered according to Table 1.

Table 1: Mass percentage of components in cow’s milk

The major minerals in milk are calcium, sodium, potassium and magnesium, which are in the form of phosphate, chloride, nitrate and caseinate. Trace elements such as sulfur, zinc, rubidium, silicon, bromine, aluminum, iron, etc. are also found in milk. The high volume of wastewater production in these industries, along with their significant pollution load, has led to strict laws for these industries in different countries.

Dairy wastewater usually produces the following phenomena when it enters running or natural waters.

- Consume water-soluble oxygen quickly and as a result will cause the death of aquatic organisms.

- They cause sludge formation in the riverbed.

- Fungi in sewage grow quickly.

- The pH of the water gradually decreased and destroyed the conditions conducive to the life of living things.

Wastewater produced in factories and dairy industries is due to land washing and CIP operations and contains large amounts of fat, COD and BOD as well as particulate matter or TSS, which is completely treated in dairy wastewater treatment.

According to the nature and type of products such as milk, yogurt, buttermilk and cheese, the wastewater treatment of dairy industry is done in the first stage by physical and chemical methods and in the second stage by biological methods. The use of anaerobic and aerobic methods and simple and advanced degreasers is one of the requirements for wastewater treatment in the dairy industry. But in general, the sources of wastewater production in these factories can be summarized in the following two main sections.

- Water for washing tanks at the place of receiving milk

- Washing water for valves, pipes and other facilities

Dairy industry wastewater treatment methods

In a simple classification, the wastewater treatment of the dairy industry and the dairy factory consists of two parts, which include the physical removal of fat and suspended solids (TSS) and the second part is the biological removal of COD and BOD agents by aerobic and anaerobic units.

As mentioned, if fats and oils enter the biological wastewater treatment units of the dairy industry, these systems will have problems and their function will be disrupted. For this purpose, pre-filtration methods are used to remove fat. Also, due to the high concentration of COD, it is necessary to use several biological units in series. It should be noted that the maximum concentration of COD input to aerobic units cannot be more than 2000mg / lit.

In general, the wastewater treatment units of the dairy industry are as follows:

- Simple uniformizer and degreaser unit: Due to the use of acidic and base solutions in the production line, in this unit, the wastewater is homogenized and its pH and flow are uniform. In a simple degreaser unit, insoluble fat and oil in the effluent, which is insoluble, come to the surface due to lightness and are collected by a shovel.

- Advanced degreasing units and suspension of suspended particles: In these units, soluble fat and also suspended solid particles of wastewater are removed physically or chemically, the most important of these methods include DAF degreaser, chemical coagulation and clotting, electrical coagulation and Or CPI fat burners.

- Anaerobic dairy wastewater treatment units: Due to the high concentration of COD, it is not possible to enter the dairy wastewater directly into the aerobic unit, because it greatly reduces the efficiency of the unit and increases the amount of sludge produced. Therefore, anaerobic methods based on gas production by anaerobic bacteria are used. The most important anaerobic treatment methods include: UASB, UABR, UAFBR, SGSB.

- Aerobic units of dairy wastewater treatment: These units are the last step of removing COD and BOD of wastewater and by injecting air with fine bubbles, part of the wastewater is turned into sludge and treated. The most important aerobic units include extensive aeration, sticky growth such as MBBR and PBBR or IFAS. In the last stage of dairy wastewater treatment, there is a sediment that the formed sludge is deposited due to high density and is removed from the system.

The purpose of wastewater treatment

The purpose of wastewater treatment is to provide better sanitation for people, keep the environment clean, spend less and use less groundwater aquifers.

In the following articles, we will talk about dairy wastewater treatment with specific products, dairy wastewater treatment applications, wastewater quality and wastewater treatment process.