Respiratory mask

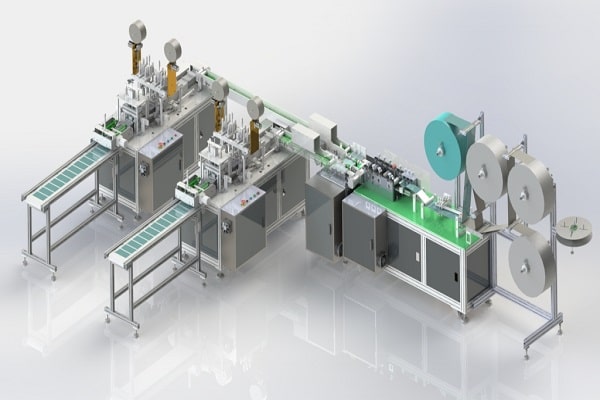

Due to the dramatic increase in the spread of coronavirus and the high demand for respiratory masks and its shortage, many decided to buy and sell a respirator production machine to launch a respirator production line.

People use a variety of masks to prevent contamination from entering the airways.

Respiratory masks act as a barrier to the entry of various contaminants and chemical toxins, and are also the only safe weapon in densely populated and polluted areas.

To produce a breathing mask, first of all, you need to know how different types of devices work.

Production and types of masks

Almost all respirators are made of non-woven fabric and are often available in two or three layers.

Recently, with the increase in the prevalence of coronavirus in our beloved country, the market of respiratory masks has become more and more attention.

Due to this extent and epidemic, almost everyone has become a consumer of this product. Today, due to the lack of raw materials for production and storage of breathing masks, it is also called white gold.

With the significant use of various types of respirators, it is predicted that the global market for this product will face many problems in the long run.

For this purpose, you should think of a solution to produce a respiratory mask or to create a mask production line at a reasonable cost.

Profitable purposes of mask production

Unfortunately, many profiteers who were always present on the scene did not even give up their profit in this turmoil, and like the people who in the past dreamed of turning iron into gold;

Using cheap fabrics that are not even suitable for the production of clothing, they sewed something similar to a mask called a washable breathing mask and sent it to the market!

You need to know that not every fabric is suitable for making a breathing mask, and anything that looks like a mask will not protect you from danger.

Respiratory mask should only be produced and manufactured according to the existing international standard conditions by the mask production machine without human intervention, it is important to observe hygienic points in preparing this product.

Respiratory mask efficiency

Respiratory masks should have at least the following: To be effective against the filtration of particles, bacteria and viruses:

-Bacterial Filtration Efficiency (BFE)

The degree to which a certain amount of bacteria enters the mask is called the filtering efficiency against the bacteria.

Particle filtration efficiency (PFE)

To prevent a certain amount of fine particles and aerosols from entering the mask is called particle filtration efficiency.

Introduction to ultrasonic welding technology

In order to increase the efficiency and efficiency of mask filtration, the respirator production machine connects the layers of the respirator using ultrasonic welding.

Ultrasonic welding or ultrasonic welding is used to weld plastic parts, although this technology is rarely used for metals.

One of the properties of this weld is its very high speed, which is done in a matter of seconds and without defects.

Therefore, ultrasonic welding technology is an ideal choice for the production of respirators.

In ultrasonic welding, the parts are amplified using ultrasound waves generated by the ultrasonic transducer and amplified, and directed to the workpiece.

Due to the molecular friction caused by the movement of ultrasonic sounds, heat energy is released and causes the piece to melt at the desired point.

The layers of the respirator, after heating, reach a degree of softening that is joined by passing through two rollers.

Ultrasonic welding because it is used in the mask production line due to no contact, short time of parts connection process, high strength and durability, no use of secondary materials for welding, very high accuracy, low cost in the long run, no pollution, quality Top and… is ideal for mask production.