Heavy oil is a cheap and polluting fuel

Heavy oil is of low quality, which is produced in the process of refining crude oil, after naphtha, gasoline and kerosene. One of the important factors in grading this fuel is its sulfur content. Fuel oil is mainly produced by the countries of Russia, Kazakhstan, Azerbaijan, Turkmenistan and Iran, and due to the fluctuation of crude oil prices, sometimes its price is lower than the price of crude oil.

This fuel is the cheapest material for supplying energy to furnaces, bathrooms, bakery ovens, lights, heaters, boilers, marine diesel engines and some power plants. The reason for the widespread use of heavy oil is its high burning heat. This fuel is usually used as a backup fuel in power plants or for small generators to produce electricity when natural gas is not available.

The role of heavy oil in air pollution

Experts believe that heavy oil plays a significant role in the air pollution of Iran’s metropolises. Currently, 90% of the country’s electricity is provided by thermal power plants that work with natural gas, diesel and heavy oil. According to the Director General of the Office of Economic, Social and Environmental Studies of Iran’s Renewable Energy and Electricity Efficiency Organization, in the last two years, the country’s power plants have consumed 67 billion cubic meters of natural gas, 6 billion liters of diesel, and 3.5 billion liters of heavy oil.

Consumption of diesel and fuel oil, especially in the cold seasons of the year and at the same time as the phenomenon of temperature inversion, plays an important role in increasing air pollution. Tehran city officials have also unofficially identified the increase in sulfur concentration as the cause of the city’s unpleasant smell.

Fuel oil purifier

The heavy oil purifier uses centrifugal force to separate impurities such as water, sludge and other particles from the fuel. This process is necessary to maintain the performance of the engines and reduce maintenance costs.

Alfa Laval Centrifuge Separators

Alfa Laval fuel separators help to increase the engine’s operating time, reduce the need for frequent filter replacements, and reduce unexpected repairs.

Alfa Laval fuel treatment solutions are designed to protect the engine and sensitive equipment and optimize fuel consumption in the long term. The company’s adaptive fuel line includes separators with engine-synchronized feed control, catalytic particulate monitoring (Cat Fine), automatic multi-fuel management and waste fuel recycling. The result of these technologies is greater efficiency, fuel savings and increased equipment life.

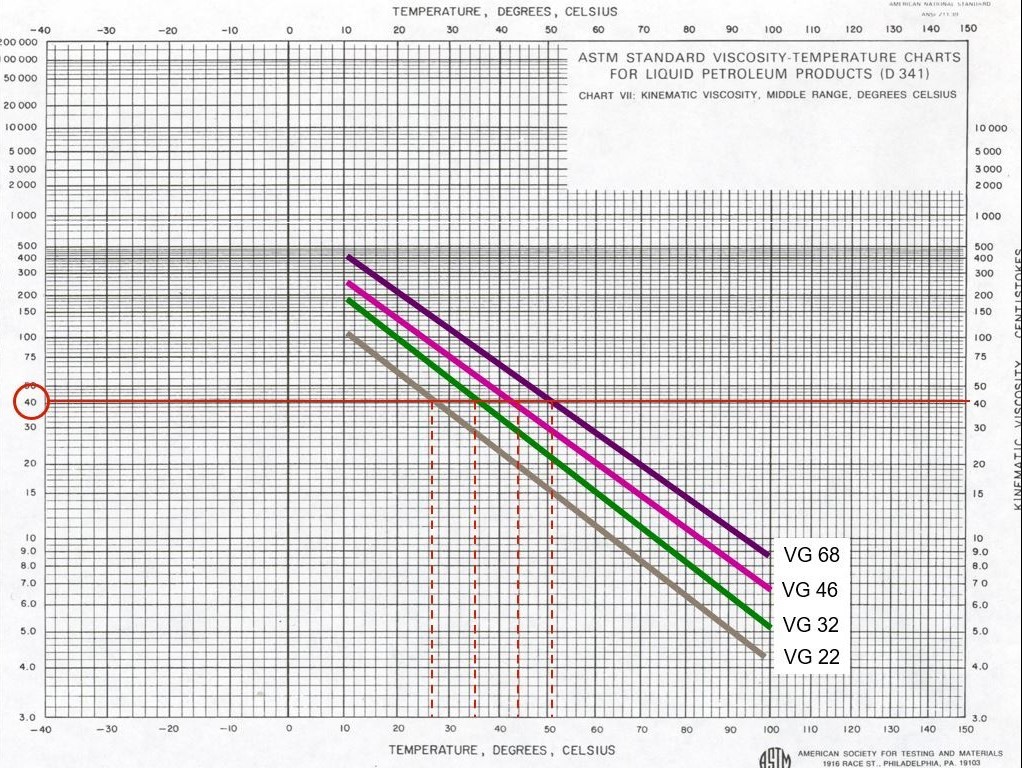

In order to optimize the fuel refining process, it is necessary to set the viscosity of heavy oil at the desired level by adjusting the temperature. The chart below shows the relationship between temperature and standard viscosity for liquid petroleum products.