With the advancement of technology in all industries and the use of automatic devices, which due to the high price and sensitivity of equipment and devices, requires the use of electrical panels to protect and control power fluctuations.

Part Sanaat Arka Company designs, manufactures and executes electrical panels based on customer needs.

Why use an electrical panel?

1- Power distribution and power supply to consumers:

In an industrial or residential complex, there is usually one or more inputs (city electricity, generators) that can feed a large number of consumers. Obviously, we have to distribute the incoming electricity to all consumers. In fact, a switchboard can have one input and many output.

2- Consumer protection and user safety:

Protection of human life, protection against fire hazard, protection of consumers against electrical disturbances such as high and low voltage, overload, short circuit and any factor that requires both electrically and mechanically. Hurt the consumer.

3- Optimization and control of consumers and equipment:

From an industry perspective, the control debate can be very traditional and old-fashioned and intelligent and modern. Like turning on a light bulb with the help of an ordinary switch or turning it on by controllers such as PLC, in any case, the electrical panel is a kind of control and protection center of our devices and equipment.

Types of industrial electrical panels based on material

-

Stainless steel and carbon steel

Carbon steel and stainless steel are both used in industrial electrical switchboards due to their high durability and corrosion resistance.

This feature makes them suitable for use in medical, pharmaceutical and food applications.

-

Aluminum electrical panel

Light weight, good strength, low cost and corrosion resistance are the main reasons for choosing aluminum.

-

Polycarbonate

Resistant to corrosion and some acidic environments.

-

Fiberglass

Fiberglass containers are resistant to chemicals.

Types of industrial electrical panels based on voltage level

1- Low voltage panels (LV)

Panels with voltage level below 1000 volts

2- Main voltage panels (main voltage – MV)

Panels with voltage level of 1000 to 36000 volts

-

High voltage panels (HV)

Panels with a voltage level of 36,000 to 400,000 volts

Types of industrial electrical panels based on how to install

1- Self-standing boards

This type of electrical panel is designed separately and then installed standing in the desired location.

Its body material is usually stainless steel.

-

Wall mounted

If this type of panel is installed inside the wall, it is called built-in electrical panel, and if it is installed outside the wall using other equipment, it is called surface mounted electrical panel.

Types of industrial electrical panels based on installation location

1-Indoor

- Outdoor

Types of industrial electrical panels based on design

- Isometric map

- Location map

- Map of power and command circuits by numbering wires and terminals

Components of industrial electrical panels

1-Contactor

2-Bimetal

3- Relay

4-key

5- Measuring instruments

6- Current or voltage transformer

7- Body or enclosure of the panel (Enclosure)

8- Communications between parts or wires and cables

9- Connecting bolts

10- Fuse

11-Copper ingots (bushes)

12- Talc

13- CT (Current Transmitter)

14- Soft starter

15-Cable Varnish

16- Thermal switch

17-Auxiliary contact

18- Terminal

19- Gland

20-insulator

21- Timer

22- Inverter

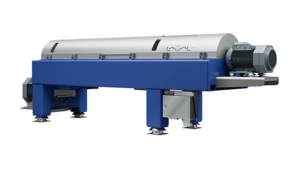

PS series standing boards

PS series boards with patterning and knowledge received from the boards of the German company Rittal are provided by Part Sanat َArka Co.

Rittal Company is the largest and most reputable manufacturer of switchboard body and specialized electrical switchboard equipment in Europe, which provides all the switchboards and switchboard equipment required by major European electrical companies.

The following is a brief overview of the benefits of these boards:

- Ease of moving equipment

- Quick assembly of electrical parts

- Ability to install Swing Frame

- Maximize the use of available space

- Ability to convert to 19-inch rack

- Locking in the panel from three points

- Sturdy and beautiful, without any sharp edges

- Ease of opening and closing side pages

- For all purposes of distribution, control, electronics and telecommunications

- The degree of protection of the panels is IP55, which is done by injecting Foam PU on all required surfaces with the Dosing Robot.

Technical specifications of the boards

- In the construction of the body of the panels, 1.5 mm sheet is used and the doors are made of 2 mm sheet.

- For wiring inside the boards, spray wires are used and to guide these wires, plastic channels with appropriate dimensions are used.

- The minimum cross section of the wires used in the control circuits is 1.5 mm and they are numbered according to the map.

- The used busbars are made of copper with excellent conductivity and a suitable thermal coating for protection is considered on them.

- Suitable rail terminals of any size are considered.

- Characteristic plates are used to identify electrical panels and German and their material is special plastic fiber, which is engraved with letters by a fully automatic pantograph machine.

- Inside the boards, there is a suitable space for placing maps and documents.

- On the roof of the panel, special hooks are installed for transporting the panels.

- The brand of electrical equipment of the panels is at the request of the buyer.