How the homogenizer works in the dairy industry

Homogenizer is one of the vital equipment in the dairy industry that plays a key role in improving the quality of dairy products. This device is used to homogenize liquids and prevent the separation of fat from milk. The homogenization process increases the shelf life, improves the taste and increases the uniformity of the final product.

What is the process of homogenization

Milk naturally contains fat particles that tend to bind together over time and form a layer of fat on the surface of the milk, which can lead to undesirable separation of the fat from the milk liquid.

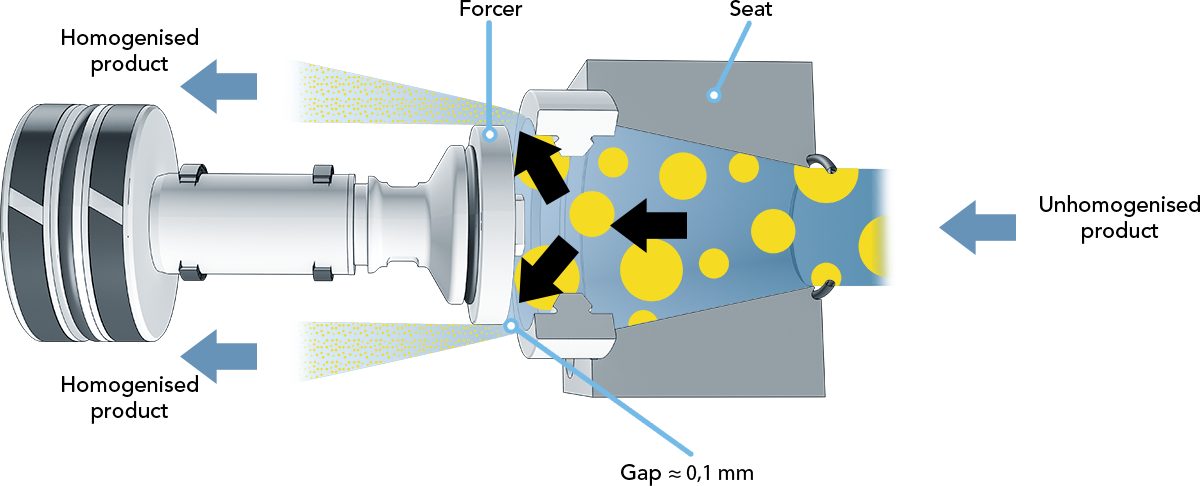

In homogenization, the milk is subjected to very high pressure (usually between 100 and 300 bar) and passed through very small valves in the homogenizer.

This pressure and passage through these valves breaks the fat particles into much smaller sizes (usually less than 2 microns).

These smaller particles spread evenly throughout the milk liquid and prevent the formation of a fat layer.

Advantages of homogenization

- Increased shelf life: due to homogenization, the reduced fat particles stick to each other less and do not form a fat layer on the surface of the product. This makes dairy products such as milk, cream and yogurt last longer.

- Improving texture and taste: Homogenization creates a softer and more uniform texture in the final product, and also, the taste of milk and dairy products become more homogeneous and have a better taste and aroma.

- Preventing the separation of fat: One of the main problems in the production of dairy products is the separation of fat from milk liquid, which affects the appearance and quality of the product. Homogenization overcomes this problem and provides a more uniform product.

Applications of homogenizer in dairy industry

The homogenizer is used in the production of a wide range of dairy products, including pasteurized milk, milk powder, yogurt, cream and ice cream. This process is not only important for improving the quality of consumer products, but also plays an important role in industrial processes such as the production of enriched milk or dairy products with less fat.

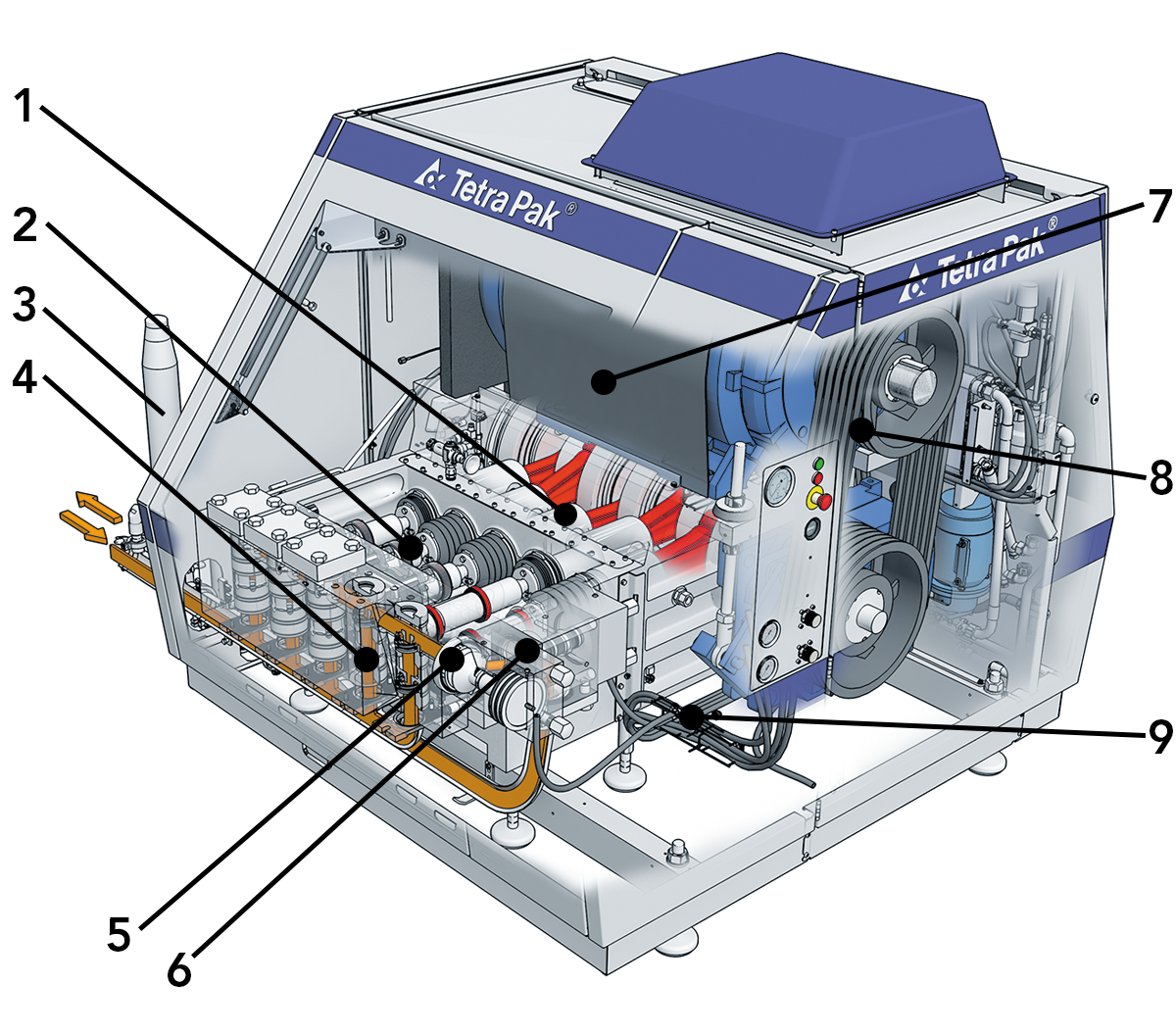

-

- Crankcase

- Pistons

- Damper

- Pump block

- first stage

- second stage

- Main drive motor

- V-belt transmission

- Hydraulic pressure setting system

conclusion

In general, homogenization is one of the important processes in the production of dairy products, which prevents the separation of fat and helps to improve the sensory, physical and chemical characteristics of the final product. The use of homogenizers in the dairy industry leads to the production of products with higher quality, longer shelf life and better taste, which are more attractive to consumers.