Separation of solids from liquids (Decanter):

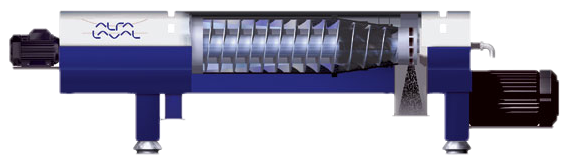

Separation of solid materials from liquids plays a key role in countless industrial processes. Centrifuge decanters of Alfa Laval company perform this important action extremely well.

How does a centrifuge work?

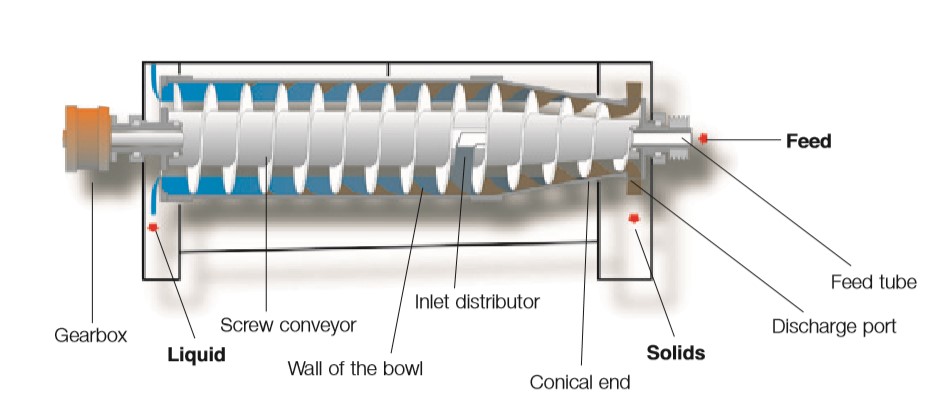

A decanter centrifuge separates solids from one or two liquid phases in a continuous process. This operation is done by using centrifugal forces which can be about 3000 times the force of gravity.

When matter is affected by such forces. The denser solid particles move to the outside, the wall of the rotating bowl, while the liquid phase with less density forms an inner central layer. Wherever necessary, different dam plates are used to change the depth of the liquid, which is called a pond.

Sediments resulting from solid materials are continuously removed from the bowl by a spiral conveyor that rotates at different speeds.

They become Therefore, the solid material is gradually plowed out of the pond and placed on top of the beach cone.

The force of the centrifuge condenses the solids and expels the excess liquid, then the dried solids are discharged from the bowl – the clarified liquid phase overflows from the dam plates located at the opposite ends of the bowl. The baffles inside the centrifuge direct the separated phases to the correct flow path and prevent any kind of cross contamination.

The speed of the spiral conveyor is automatically adjusted by using a variable frequency drive (VFD) in order to regulate the changes in the load of solids.

Industrial applications of the process:

- Mineral processing industry: producers of kaolin soil, calcium carbonate, bentonite and titanium dioxide.

- Petrochemical industry and gas-oil exploration: gas and oil exploration, oil refineries and related industries, lubricating oil additives and recovery of waste oil flow.

- Organic chemical industry: final products and aqueous intermediates

Polymer industry: thermoplastic materials including PVC, polypropylene, polystyrene, synthetic rubber and fibers. - Chemical industry of mineral materials: decolorizers, acids, silica products and fertilizers

Ethanol production:

The processing of industrial alcohol that is used in washing and the rest of the molasses of Fernstor

Starch processing:

From wheat, corn and potato

Waste recovery:

Recovery and restoration of wastewater flows from the above-mentioned sectors.

Food consumption:

- Animal protein: side processing of meat and fish, surimi processing, recovery of edible protein

- Brewing water: recovery of extract, yeast

- Coffee and tea: extraction of instant coffee and tea

- Dairy: recovery of casein, lactose, whey and cheese

- Edible oil: clarification of palm oil, olive oil and pressed seed oil

- Fruit juice: extracting currency from fruits, strawberries and vegetables

- Pectin: Recovery of extracted pectin

- Vegetable protein: extraction of soybean oil, oil seeds and leguminous products