Types of infant formula

Baby formula is divided into several main categories based on specific ingredients and uses:

1. Standard Infant Formula:

- Suitable for babies who are healthy in terms of digestion and do not have special needs.

- Its ingredients include cow’s milk protein, lactose, vegetable fats and minerals and vitamins.

2. Hypoallergenic Formula:

- It is designed for babies who are allergic to cow’s milk protein.

- The proteins in this type of formula are hydrolyzed (completely broken down) to reduce the risk of allergies.

3. Lactose-Free Formula:

- Suitable for babies with lactose intolerance.

- Lactose has been replaced with sugars such as glucose or maltodextrin.

4. Soy-Based Formula:

- For babies who cannot tolerate animal protein.

- It is produced on the basis of soy protein and without lactose.

5. Anti-Reflux or Comfort Formula:

- Contains thickeners such as starch to reduce acid reflux and reflux.

- Suitable for babies with mild digestive problems.

6. Follow-On Formula:

- Designed for babies over 6 months.

- Its ingredients contain more iron, calcium and minerals for faster growth of the baby.

7. Specialized Formula:

- It is produced for babies with special conditions such as premature infants, metabolic problems or certain diseases.

- It has a special formulation based on the special needs of the baby.

The process of producing infant formula

Production of infant formula is a sensitive and complex process that requires compliance with high health and nutritional standards. This process is divided into the following steps:

1. Selection and preparation of raw materials:

- Ingredients include fresh milk, modified proteins (such as casein and whey protein), vegetable fats (such as palm oil or soybean oil), vitamins and minerals.

- Raw milk is pasteurized and its fat and protein are adjusted to provide nutritional balance.

2. Homogenization:

- Milk ingredients are homogenized with special devices so that the fat particles are evenly distributed.

- This step is done to improve digestion and increase product stability.

3. Concentration:

- Milk is condensed by evaporation devices to remove part of its water.

- This step increases the concentration of nutrients and prepares for the drying step.

4. Adding nutrients:

- At this stage, vitamins, minerals, probiotics, and essential fatty acids (such as DHA and ARA) are added to the mix.

- The exact composition of these ingredients is adjusted to simulate breast milk and match the needs of the baby.

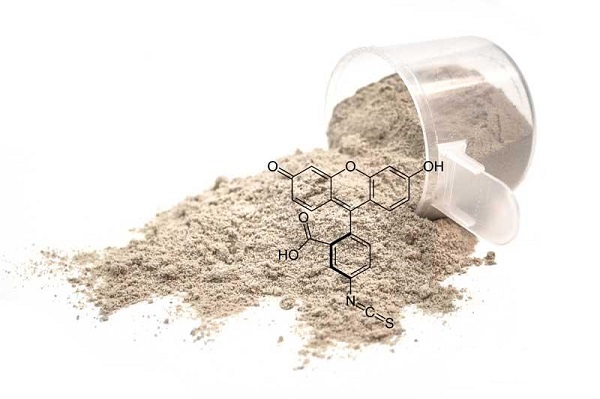

5. Spray Drying:

- The concentrated compound is sprayed through special nozzles in the form of fine particles inside a warm chamber.

- High temperature air enters the chamber and the water in the composition evaporates, resulting in the production of dry powder.

6. Cooling and packaging:

- The produced powder is cooled and packaged in controlled environments.

- The packages must be completely resistant to the penetration of moisture and pollution.

7. Quality control:

- All production steps are under the strict supervision of health standards.

- Various tests are conducted to ensure the quality and safety of the product.

Key features of infant formula

- High nutritional value: Contains all the nutrients needed for the growth of the baby.

- Easy to digest: Proteins and fats are optimized for the baby’s digestive system.

- Safety: Manufactured under strict standards to ensure baby’s health.

- Long shelf life: Air and moisture resistant packaging allows for long-term storage.

conclusion

Baby formula plays an important role in feeding babies with their special formulation. The production of these products requires advanced technology and very high precision to ensure both the nutritional quality and safety of the product. Considering the different types of powdered milk, choosing the right product should be done based on the special needs of the baby and consultation with a specialist doctor. Using high-quality powdered milk can help the growth and better health of the baby.